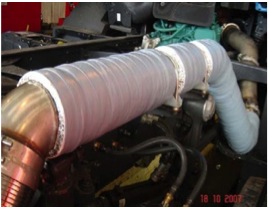

VitriFlex - Pipe insulation system

The Vitri®Flex system consists of two main components: high temperature-resistant textile fibres which combined with a reflective metal foil form a flexible tape, and an outer protective mantle. The combination of these materials enable it to dilate during installation, allowing to compensate shape-related irregularities and achieving a smooth surface. This is required to ensure a good fit in particular around pipe bends. Vitri®Flex tapes are used in layers depending on the prevalent application temperature. For most diesel exhaust systems, three layers are sufficient.

The outer layer consists of a self-vulcanising and resilient high-temperature elastomer that is used to protect the insulating layers from exterior factors. The outer layer is self-vulcanised in order to achieve an oil and water-resistant protective outer mantle. Flame retardant according to UL 94:V - O.

For more information on this subject, refer to the information brochure below!

Fields of application:

Vitri®Flex was designed to maintain the gas temperature in exhaust pipe systems with downstream emission control systems. Furthermore, Vitri®Flex is also used as thermal insulation material.

Advantages of Vitri®Flex:

Reduces the engine compartment temperatures in agricultural, forestry and construction machines, reduces the fire hazard, exhaust pipe insulation in generator sets, locomotives and ships.

The Vitri®Flex system is specially certified according to EC-Type Examination Certificate (module B) as non combustible insulation material for marine industry applications.

For approval in rail vehicle design, the material has been classified as M2 (flame retardant) according to the standard NF F 16-101.

Properties:

- easy fitting - no special tools required

- fits all pipe diameters

- insulation thickness can easily be varied along the pipe

- stays permanently flexible, can accommodate expansion joints

- efficient, high density insulation acts as heat store,

reduces temperature fluctuation and heat loss - fully vibration-resistant

- resistant to bio-diesel, urea and salt water spray

- oil and water resistant coating

- outer layer can be easily repaired or replaced

- tough outer layer resists frost and stone chips

- long-life, thus cost effective

- tolerates steam pressure cleaners if used properly

Contact

Frank Bischof

Vertrieb

Phone: +49 (0) 68 21 / 29 000-81

Mobil: +49 (0) 171 / 20 46 173

Fax: +49 (0) 68 21 / 29 000 - 77

fbischof@culimeta-automotive.de